Articles

Momentive Demonstrating Innovation and Productivity of LSR

October 06, 2016

Product demonstrations of Silopren* liquid silicone rubber at K 2016 highlight developments in hard-soft design, thermoplastic adhesion, and process efficiency

Waterford, N.Y. (October 6, 2016) – Momentive Performance Materials Inc. (“Momentive”) will feature Silopren* liquid silicone rubbers (LSR) in a variety of live demonstrations in collaboration with industry partners at K 2016, taking place October 19-26 in Düsseldorf, Germany. These demonstrations will showcase the processing qualities and benefits of Momentive’s elastomer products for injection molding.

In booth B15 in Hall 6, Momentive will feature 2-component LSR on LSR molding with

Silopren LSR 2670 liquid silicone rubber in cooperation with Elmet and Arburg. Being a full system supplier, Elmet created a 4+4 cavity mold manufacturing egg-holders and built a fully automated turn-key cell by integrating an Arburg injection molding machine with its own peripheral devices and dosing system. The installed close-loop controlled color injection at the dosing system is a new feature which will be presented for the first time at K-fair. This innovation controls and documents the real amount of color or additive in the material, which is particularly relevant to the healthcare segment. The special system concept allows for 2-component molding on a 1-component LSR standard machine with only one LSR dosing system.

Silopren LSR 2670 liquid silicone rubber in cooperation with Elmet and Arburg. Being a full system supplier, Elmet created a 4+4 cavity mold manufacturing egg-holders and built a fully automated turn-key cell by integrating an Arburg injection molding machine with its own peripheral devices and dosing system. The installed close-loop controlled color injection at the dosing system is a new feature which will be presented for the first time at K-fair. This innovation controls and documents the real amount of color or additive in the material, which is particularly relevant to the healthcare segment. The special system concept allows for 2-component molding on a 1-component LSR standard machine with only one LSR dosing system.

“We are proud to showcase the processing benefits of our LSR in close cooperation with our industry network of leading suppliers,” said Holger Albrecht, Vice President, Elastomers. “Momentive has paved the way for wide adoption of LSR technology in the automotive, healthcare and consumer goods industries, and our newest product developments bring new functionalities and design flexibility to critical applications.The applicability of LSR for multi-component molding will also be shown in the Arburg booth, A13 in Hall 13, in partnership with Rico Elastomere Projecting. In this demonstration, the automated manufacturing of a yet undisclosed innovation will be showcased with a hard-soft LSR combination of Silopren LSR 2670 liquid silicone rubber for harder component and an inlay of the softer Silopren LSR 2620 liquid silicone rubber.

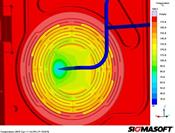

The excellent consistency and processability of Silopren LSR 2670 liquid silicone rubber will also be presented via a designer article application from CVA Silicone in the Sigmasoft booth, B31 in Hall 13. The demonstration will be conducted on an electrical e-mac 100 injection molding machine with integrated e-pic handling supplied by Engel. This process demonstrates that Momentive’s Silopren liquid silicone rubbers can be considered for use in even the most complex manufacturing challenges. The molded part, known as “Ursula,” is a protective carrier for bottles and has received an award at the Biennale du Design Français. Sigma Engineering, the expert for rheological and thermal simulations, will showcase the virtual process: how the highly complex shape of the Ursula part is actually filling and crosslinking, calculated by the Sigmasoft software.

molding cycles of typical engineering thermoplastics and its option of excellent primerless adhesion. The demonstration confirms the benefit of this technology in many hard-soft combinations for consumer goods and automotive industries.

molding cycles of typical engineering thermoplastics and its option of excellent primerless adhesion. The demonstration confirms the benefit of this technology in many hard-soft combinations for consumer goods and automotive industries.

In the same booth, Dr. Boy will also show the fully automated manufacturing of single wire seals in a 128 cavity turnkey stem developed by Elmet. The self-lubricating Silopren LSR 3186/50 liquid silicone rubber is broadly used in the automotive industry for connector seals.

“We are proud to showcase the processing benefits of our LSR in close cooperation with our industry network of leading suppliers,” said Holger Albrecht, Vice President, Elastomers.

“Momentive has paved the way for wide adoption of LSR technology in the automotive, healthcare and consumer goods industries, and our newest product developments bring new functionalities and design flexibility to critical applications.

“Momentive has paved the way for wide adoption of LSR technology in the automotive, healthcare and consumer goods industries, and our newest product developments bring new functionalities and design flexibility to critical applications.

Three of these five Momentive material demonstrations at K 2016 are based on Silopren LSR 2670 liquid silicone rubber. This year, Silopren LSR 2670 liquid silicone rubber highlights a 20 year success story. Launched in 1996 as the hardest (70 Shore A) version of the new LSR 26xx series – and optimized for high tear-resistance and fast curing -- Silopren liquid silicone rubber’s well-balanced properties led to a fast adoption in critical high temperature applications. Additionally, the ability of Silopren LSR 2760 liquid silicone rubber to be considered for specific applications in contact with human skin or food became the basis for broader applications in food processing and wearable devices.

Visit booth B15 in Hall 6 to learn more about the complete portfolio of Momentive Silopren liquid silicone rubber and other silicone elastomer solutions. Additional information is available at www.momentive.com.

About the Company

Momentive Performance Materials Inc. is a global leader in silicones and advanced materials, with a 75-year heritage of being first to market with performance applications for major industries that support and improve everyday life. The Company delivers science-based solutions by linking custom technology platforms to opportunities for customers. Momentive Performance Materials Inc. is an indirect wholly-owned subsidiary of MPM Holdings Inc. Additional information about Momentive and its products is available at www.momentive.com.

Media Contact:

Tina Reiber

+1-518-233-2688

Dominik Schlefers

+49 (0)214 30 35370

Dominik.Schlefers@momentive.com

###

*Silopren is a trademark of Momentive Performance Materials Inc.

New from Momentive

Momentive NXT Silanes: Delivering Sustainable Solutions

American Coatings Show 2024

April 30-May 02, 2024 | Indianapolis, Indiana, United States | Register

VIEW ALL TRADE SHOWS*The marks followed by an asterisk (*) are trademarks of Momentive Performance Materials Inc.